Aluminium receivers

Lightweight, particularly suitable for high performance air conditioning on transport vehicles and other applications.

Our products are entirely manufactured at our Pordenone facility and have conquered the main international markets, with an export quota reaching 80% of total turnover. That’s thanks to their controlled, certified quality, performance and competitiveness coupled with our professional, customised service. The Denaline strategies are designed to ensure long-term stability.

Investing in training our workforce and collaborators and in innovation has allowed us to develop a fully integrated, technologically advanced production cycle.

As a company we encourage talent, free thinking and responsible behaviour and we nurture our collaborators, who have ample freedom to make decisions according to agreed guidelines..

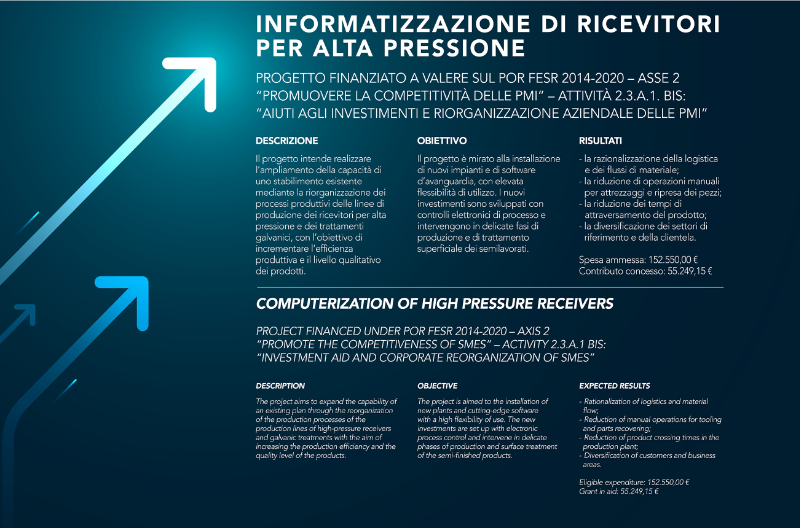

Our company has received a non-repayable grant for the following project: “Computerisation of high pressure receivers” under Competition POR FESR 2014-2020, Activity 2.3.a.1 bis “Grants to help SMEs make technological investments.”

The aim of this project is to extend the capacities of an existing production plant by reorganising the production processes of the lines producing high-pressure receivers and involved in galvanic treatments, to the purpose of increasing production efficiency and product quality.

The project’s goal is to instal new equipment and cutting-edge software that is very flexible to use. The new investments are developed with electronic process controls and come into action in delicate production phases and during the surface treatment of semi-finished products.

The expected results consist in the rationalisation of material logistics and flows, the reduction of manual operations for tooling and reworking of pieces, and the reduction of product throughput times.

Expense permitted: 152,550.00 Euro

Grant awarded: 55,249.15 Euro

Our company has received a non-repayable grant for the following project: “New, flexible, efficient production processes backed by «Industry 4.0» technologies, under Competition POR FESR 1.2.a.1 “Innovation – food and drink, strategic production chains, maritime technologies and smart health” (2017 Competition).

This project regards the introduction of a new process for the company that wants to acquire the technological and computer science know-how necessary to automate and control in real time – even remotely - one of the main production processes of the company, i.e. the square valve body, one of the cruxes of the factory’s flow.

Implementation of this project will achieve the following goals:

- a minimum 2% increase in turnover on current volumes;

- acquisition of new sectors of the industrial and commercial refrigeration market;

- acquisition of new customers.

Expense permitted: € 259,898.73

Grant awarded: € 103,959.49

Our company has received a non-repayable grant to conduct a research project under COMPETITION POR FESR 2014-2020, Activity 1.2.a “Incentives to companies for collaboration in industrial research and experimental development – Food and Drink, Strategic production chains”.

By means of this project, Denaline intends to study and define new organisational models able to support and develop new operational strategies, guaranteeing management of the new technological solutions identi- fied, based on the use of intelligent equipment.

The following end results are expected from the project:

- start of a new organisational model

- set-up of some production processes

- implementation of ongoing control

- implementation of automatic adjustments to accura- tely check dimensions

- intergration and interfacing of various operational environments

- remoting software.

Denaline SpA has been operating for 40 years in Pordenone, North Eastern Italy, a city with a thriving entrepreneurial scene which has over the years kept pace with innovation and technology, successfully developing numerous manufacturing companies and thus generating growth for the local area.

Set up in 1977 by an engineer, Mauro Avanzini, founder and current CEO of the company, Denaline started out selling products for air conditioning and industrial refrigeration such as tube condensers, liquid receivers and bronze connections, mostly within the Italian territory.

Manufacturing of the first valves and rotalock connections started in 1984, in a rented 300 sq.m. plant just outside Pordenone.

In 1990 in line with a rising demand for industrial refrigeration products and components from major global firms, the company decision makers opted for setting up the first company-owned facility in Pordenone’s new industrial zone, on a 1,400 sq.m. site including manufacturing space, offices and services. In 1996 the manufacturing facility was expanded by a further 2,100 sq.m.

Simultaneously, the management, organisational, technical, sales, administration, research, automated warehousing and logistics departments were all upgraded and made more efficient over the years.

Quality, service, competitiveness and responsible, well-considered corporate decisions led overseas turnover to reach 80% of the overall figure.

Our clients are guaranteed controlled, tested and certified products, exclusive patented technical and industrial solutions, and a registered brand that's protected at European and world level via direct correspondents.

The current site, which doubled in size between 2006 and 2008, sits on 8,500 sq.m., including 900 sq.m. of offices and services. Manufacturing capacity: 250,000 receivers and over a million valves per annum.

Our manufacturing processes and systems have been a continuing focus for the company, with the goal of continuing improvement of production cycles, energy saving, environmental responsibility and scrupulous attention to mental and physical working conditions for our workforce .

A fine example of Made in Italy drive and ability shaped by an intense passion for working hard that has always been shared by the Denaline staff - from the current company president Mr Mauro Avanzini to senior management and across the entire workforce.

A leader is not a leader unless he’s not only thinking about technological innovation and product performance, but also about our shared heritage: the environment.

Denaline has always focussed on green issues which means

- developing a new category of products using natural, environmentally compatible refrigerants,

- systems in which the components are fitted are low environmental impact,

- long product life cycle, another important sustainability factor.

Our products, industrial processes, from design to disposal, and work environment are all particularly environmentally sustainable, environmentally clean and economically efficient, and we ensure energy saving in offices and services

Further to an idea of the Municipality of Pordenone, Denaline has joined the “Solidarity for Transport Services on the Municipal Territory” project by contri- buting to purchase a new vehicle to transport patients requiring treatment in specialist centres.

This free transport project has been developed by a specialised company that makes specific, accessorised vehicles available to Social Services who use them to transport people with reduced mobility.

Denaline manufacturing has always been original, exclusive and effective in all company processes, starting with research and development of innovative ideas that satisfy the needs of our customers, optimisation and customisation of products aimed at containing costs, improving quality and performance of those products and systems to the manufacturing processes where continuous improvement is an essential element of our quality system, right up to after-sales service.

Denaline has developed many products internally over the years and these are thus patented or patent-pending. We constantly invest in research and development, new manufacturing technologies and both internal and external resources, in order to create cutting edge products that are both efficient and reliable.

enaline’s products comply with the UNI EN

ISO 9001 – 2015 standards, with the European directive 2014/68/EU (Pressure Equipment Directive) and with UL Standards.

If requested by the Customer, we can arrange for our products to be approved in compliance with the requirements specified by the ATEX 2014/34/ EU (group 2) European Directive and by the AS 4343 Standard (for the Australian market).

As one of the leading companies in the world in innovation, it is essential for us to comply with the main international regulations.

Denaline has obtained compulsory TR EAC certification of product for companies who export / import and circulate products in Russia, Belarus and Kazakhstan.

Aluminium, stainless steel and copper are the materials DENALINE uses to create a new category of products that use environmentally compatible refrigerants (carbon dioxide – subcritical/transcritical ammonium and hydrocarbon cycle): liquid receivers, oil separators (patent pending), mufflers, by-pass valves, safety valves, three-way valves, liquid/gas indicators for electronic sensors, valves with copper connections and more. Denaline has developed many products internally over the years and these are thus patented, such as reversible molecular sieve filter driers, sight glasses, liquid and moisture indicators welded directly onto receivers with new technology, valves and refrigerant fluid tubes with incorporated moisture sight glasses and liquid indicators.

The quality of our company organisation and innovative technology allows us to supply various sectors, offering a complete range of products and handling a widely diverse range of requirements:

- industrial and commercial refrigeration

- temperature-controlled transport,

- rail and marine applications

- air conditioning systems

- systems designed for specific sectors.

- Aluminium liquid receivers NEW (Photo)

Technical specifications upon request

- Liquid receivers

Vertical receivers Type AV 45 bar

Vertical receivers Type DNL 45 bar

Horizontal receivers Type AH 45 bar

Vertical receivers Type BV 45 bar

Horizontal receivers Type BH 45 bar

Vertical receivers Type CV 45 bar

Vertical receivers Type TKV 33 bar

Horizontal receivers Type CH 45 bar

Horizontal receivers Type TKH 33 bar

Vertical receivers Type DLV -CO2 (R744) 130 bar NEW (Photo)

Horizontal receivers Type DLH-CO2 (R744) 130 bar NEW

Horizontal and vertical till diameter 1200 mm NEW

- Components for receivers

Elbow connections – patented moisture sight glasses

ODS-SAE-NPT-O-ring-Rotalock connections- soldering valves

- Suction accumulators

From caps 34 bar

From tube max. capacity 320l 45 bar

With tube condenser 45 bar

For CO2 (R744) 130 bar NEW

- Oil receivers

Capacity from 5.7l to 30l 45 bar

From tube max. capacity 30l for CO2 (R744) 130 bar NEW (Photo)

- Mufflers

From caps 45 bar

From tube for CO2 (R744) 130 bar NEW

- Oil separators with oil reserve NEW (Photo)

Capacity 0.4-1.7l max compressor displacement 14m³/h

Capacity 3.4-22.0l compressor displacement from 10 to 110 m³/h

Capacity 35-89l compressor displacement from 75 to 300 m³/h

Capacity 50-310l compressor displacement from 120 to 700 m³/h

Capacity 2.8-12.7l compressor displacement from 8 to 60 m³/h

for CO2 (R744) NEW (Photo)

- Horizontal water condensers NEW (Photo)

Technical specifications upon request

- Molecular sieve filter driers

With SAE connections NEW (Photo)

With ODS connections NEW (Photo)

With replaceable cartridge NEW (Photo)

With liquid reserve

- Mechanical filters

Replaceable filter cartridge NEW

Non-replaceable filter

- Valves for refrigerant fluids groups I and II PED

Rotalock valves with flare connections (SAE)

Rotalock valves with solder connections (ODS)

Rotalock valves with copper ODS connections NEW (Photo)

Angle valves to sold

Angle valves for CO2 (R744)

Flanged valves with flare connections (SAE)

Flanged valve with ODS connections

Flanged valve with copper ODS connections NEW (Photo)

Flanged valve for CO2 (R744) NEW (Photo)

Horizontal rotalock valves with O-ring connection

Valves for panels

Vertical valves with bracket

Valves with threaded support and copper ODS

Valves with threaded support and SAE or ODS inlet/outlet

Vertical valves with rotalock inlet

Hexagonal vertical valves with copper ODS

- Three-way dual shut-off valves NEW (Photo)

NPT or rotalock inlet and NPT outlet

With adaptor

For CO2 (R744) with NPT inlet

- Safety valves

Free outlet NEW (Photo)

Piped outlet NEW (Photo)

By-pass protection valves for refrigerant compressors NEW (Photo)

- Ductile cast iron valves

For refrigerant fluids group II PED

For NH3 (R717) NEW (Photo)

For CO2 (R744)

- Flanges

Oval flanges for valves

Cast iron flanges

- Gaskets

- Ball valves NEW (Photo)

For refrigerant fluids group II PED 45 bar

For CO2 (R744) up to 130 bar

For NH3 (R717)

- Liquid and moisture indicators

ODS-SAE-male-female-O-ring connections NEW (Photo)

Moisture sight glasses for refrigerant fluids group I and II PED NEW (Photo)

Liquid and moisture indicators for CO2 (R744) NEW (Photo)

- Flanges for ≥100l receivers and ductile cast iron valves

- Gaskets for flanges and ductile cast iron valves

- Elbow rotalock connections for all fluids and CO2 (R744)

- Rotalock connections for all fluids and CO2 (R744)

- Connections for all fluids

- Nuts and shanks

- Special connections upon request for all fluids

- Brass elbows

- Brass fittings

- Brass nuts for inch /metric tubes

- Brass tees

- Access valves

Lightweight, particularly suitable for high performance air conditioning on transport vehicles and other applications.

With special treatments and surface coatings, designed to resist working pressure PS up to 200 bar.

For special uses which require a high hygiene coefficient and excellent resistance to aggressive chemicals.

(Subcritical and transcritical applications) equipped with patented technology welded level indicators or,

alternatively, with screw-in indicators, rotalock inlet/outlet valves, mounting brackets

and various types of connections.

With oil reserve and incorporated oil filter designed for compressor capacity up to 120 m3/h and working pressure PS up to 130 bar.

Designed to guarantee excellent performance , compact dimensions. Supplied with delivery valve and safety valve upon request.

With ODS or SAE connections: Compared to a traditional solid cartridge, the molecular sieve ensures better water absorption and longer filter life.

Available from 1 to 4 replaceable cartridges – 100% molecular sieves or 80% molecular sieves -20% activated alumina- with up to 3” ODS connections.

Resistant to working pressure up to 150 bar and working temperature TS -40°C/+200°C, they can also be manufactured with movable flange so that the valve case and ODS become adjustable to client requirements.

Make brazing more economical and simple for the operator, with a considerably lower risk of leaks.

Made of galvanised steel - designed to ensure low pressure drops, can be supplied with safety valves upon request.

Made of galvanised steel - extremely reliable for semi-hermetic compressors.

Suitable for both transcritical CO2 systems and NH3 systems.

Up to 54 mm and designed to withstand working pressures of up to 120 bar.

with moisture indicator for liquid level sensors. With resistance of over 1000 hours in saline mist, for applications in any environmental condition.

Ideal for working pressures PS up to 45 bar and working temperature TS -40°C/+100°C

designed to withstand maximum working pressure PS of 120 bar and working temperature TS between -40°C and +110°C